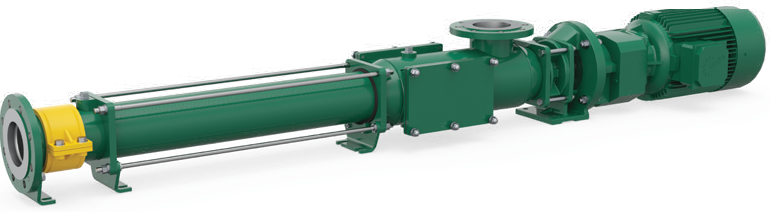

Roto KWIK Pumps

Built on the Maintenance in Place (MIP) Platform, Roto KWIK Pumps have been specially designed and developed to provide easy maintenance with minimum service time while saving on overall maintenance costs.

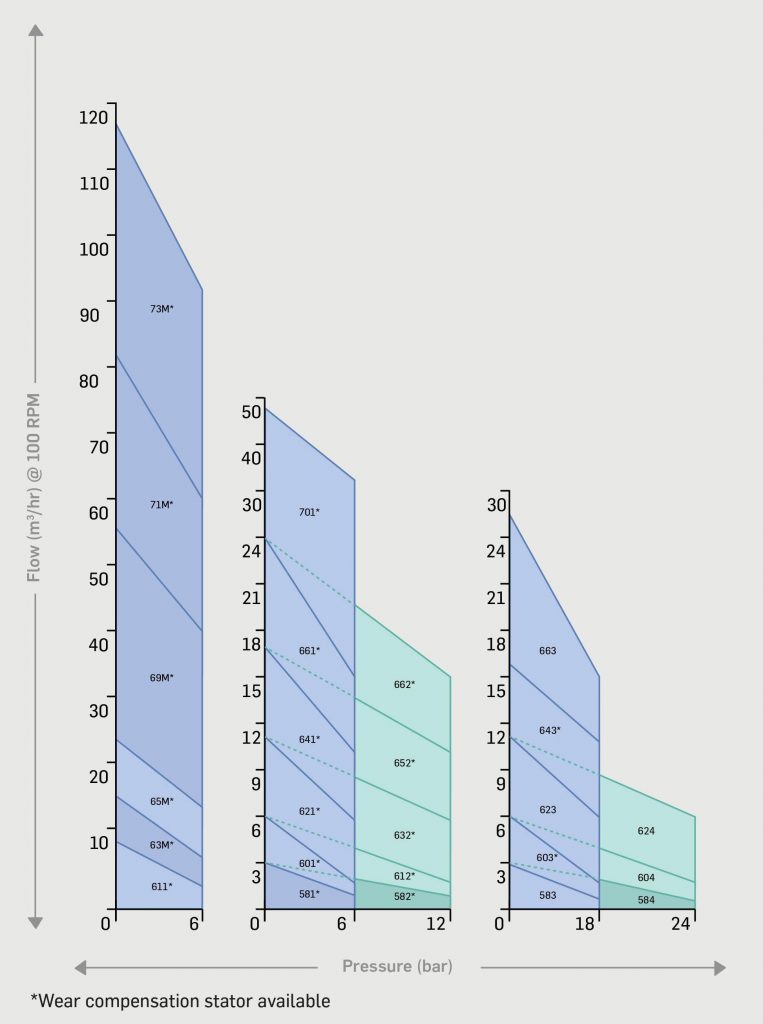

Performance Summary:

| Capacity | Up to 340 m3 /hr | Viscosity | Up to 30,000 cSt |

| Pressure | Up to 24 bar | High Solid Content | Up to 7% |

Distinctive Advantages

- Quick maintenance of pumps without dismantling the suction and delivery pipelines.

- One piece construction of stator eliminates any risk of media leakage unlike split stator design.

- Installed Roto Progressive Cavity Pumps can be easily converted to Roto Kwik Platforms with minimal changes in pipeline.

- No need of extra dismantling space.

Exploded View

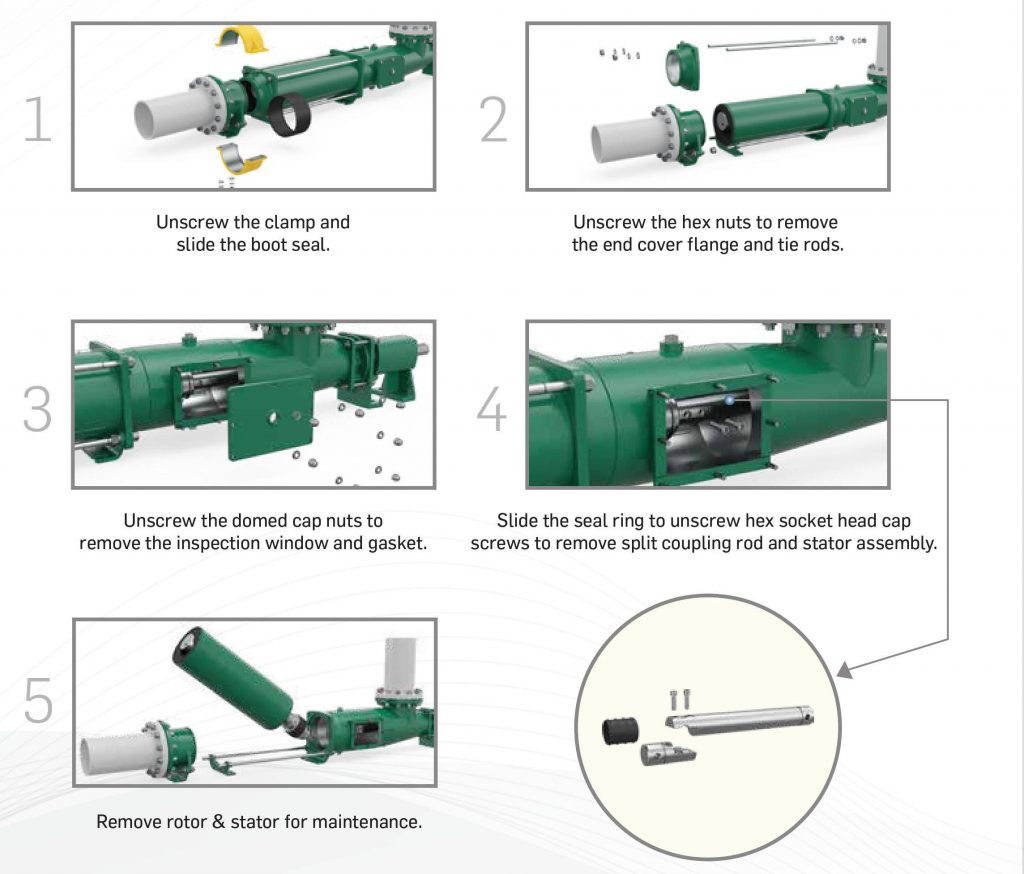

1. Clamp

Specially designed clamp enables quick removal of rotor and stator without dismantling discharge line.

2. Optimised Rotor Stator Geometry

Improved rotor stator geometry minimizes wear due to lower rubbing velocities

3. Xtra Value Universal Cardan Joint

The Cardan type of UJ joint employs two sets of perpendicular pins, each providingfreedom of angular movement, which facilitates smoother transmission of angular loads. It also withstand higher axial loads.

4. Split Coupling Rod

Enables quick dismantling of pumping elements from the coupling rod.

5. Dual Inspection Windows

Provides access to split coupling rod and also allows removal of any blockage.

5 Quick & Simple Steps To Dismantle Rotor & Stator

Dismantling & re-assembly of the Roto KWIK range of pumps is very simple, a single person can complete the required tasks in a matter of few minutes. It results in significant reduction in maintenance time and labour cost. Maintenance Engineer will need standard tools to dismantle/assemble the pump.

Performance Curves