Roto Pumps is one of the leading Food Pumps manufacturers and suppliers. Food Pumps are a subtype of progressive cavity pump and are used in Food & beverage processing, pharma, chemical, wine 7 brewery industries. These pumps can be used to transfer as well as mix liquid and semi-liquid materials. Roto’s top-quality Food Grade Pumps can be used to efficiently transfer highly viscous and sheer-sensitive liquids while maintaining the quality and hygiene of the products. The metallic parts that comes in contact with the food items are built with smooth-finished stainless steel. The stator fitted inside these pumps is built with metal-bonded aseptic food grade elastomeric which repels oil and fats. A type of Positive Displacement Pumps, these pumps can efficiently maintain a smooth flow even at high discharge pressures. Roto’s Food Grade Pumps are highly economical as they are extremely easy to maintain and clean.

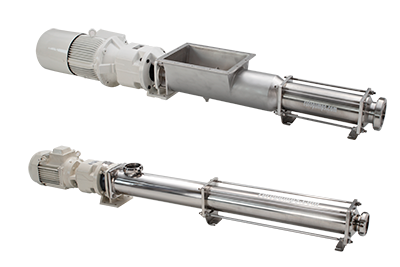

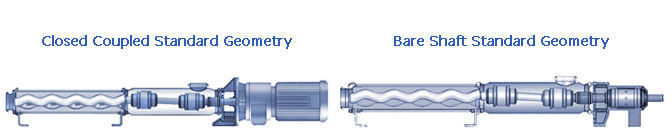

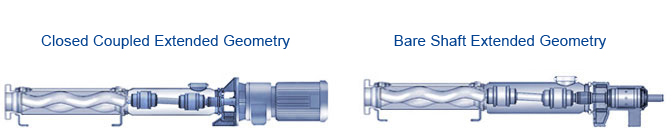

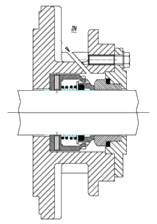

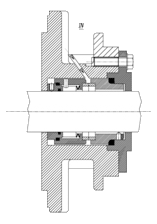

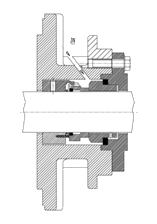

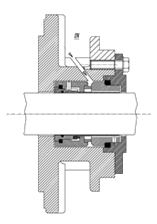

DM Series Pump

Capacity: 86 m3/hr

Pressure: up to 24 bar